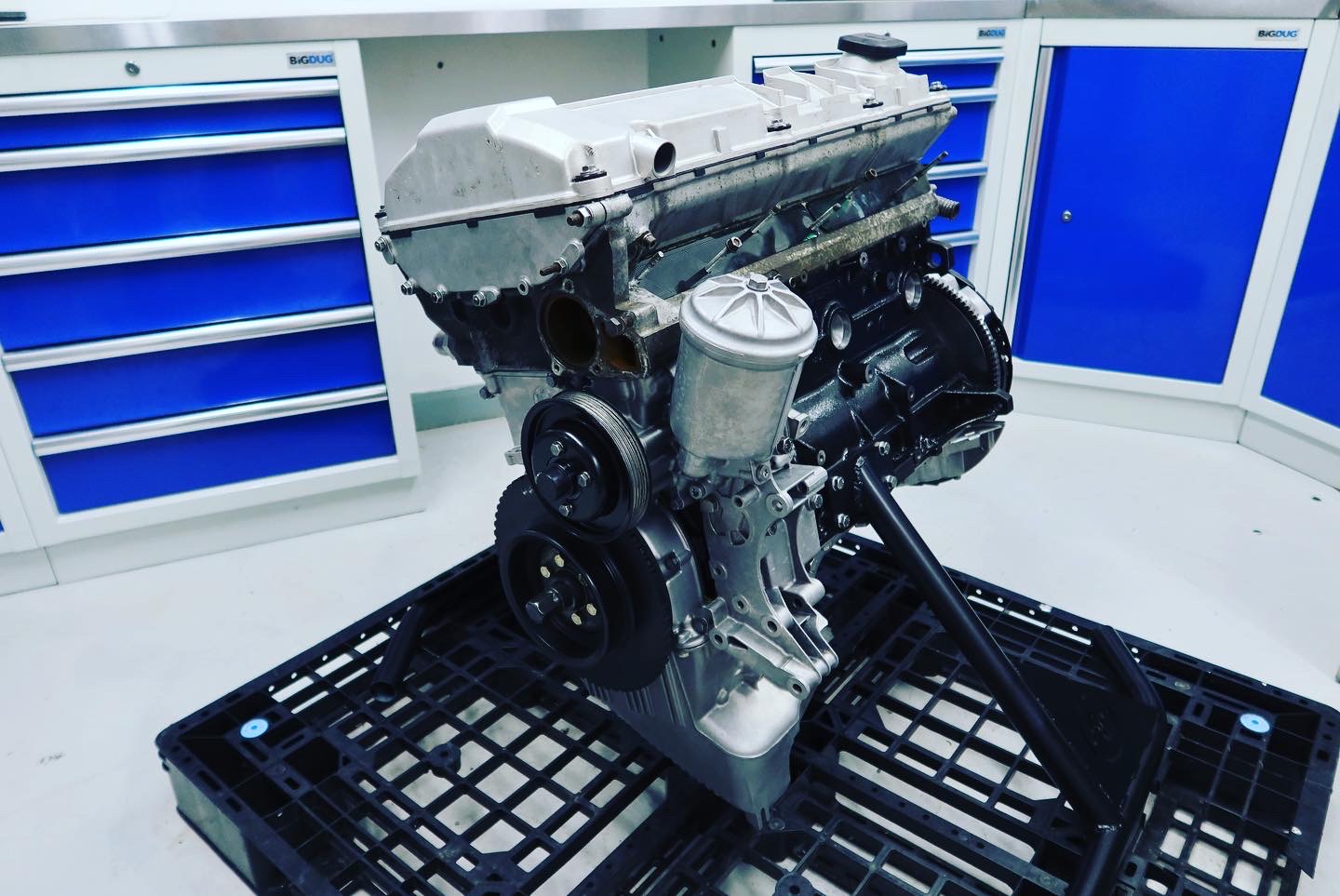

Workshop Journal: Jack’s M50 Turbo Engine Build

Jack’s M50 engine came to us as a box of bits, with unfortunately a number of issues to overcome. However, with the goal of a 600+bhp E30 turbo application in mind, we had no problems getting the build specification set and letting the build unfold.

Specification includes:

- Wiseco Pistons (85mm, 8.8:1)

- SP Components Rods

- ARP Head Studs

- Athena Cut-Ring Head Gasket

- Elring Gasket Sets

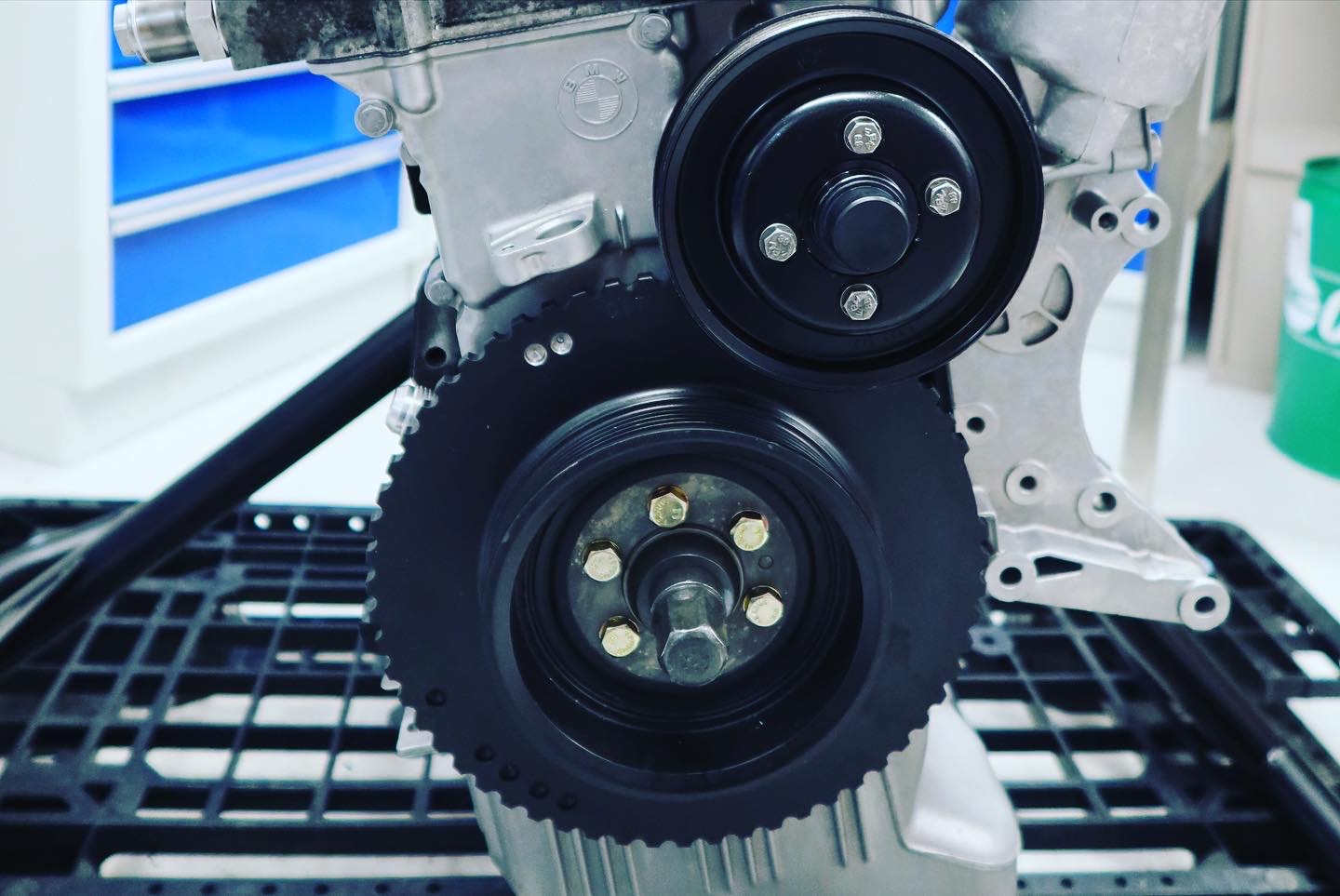

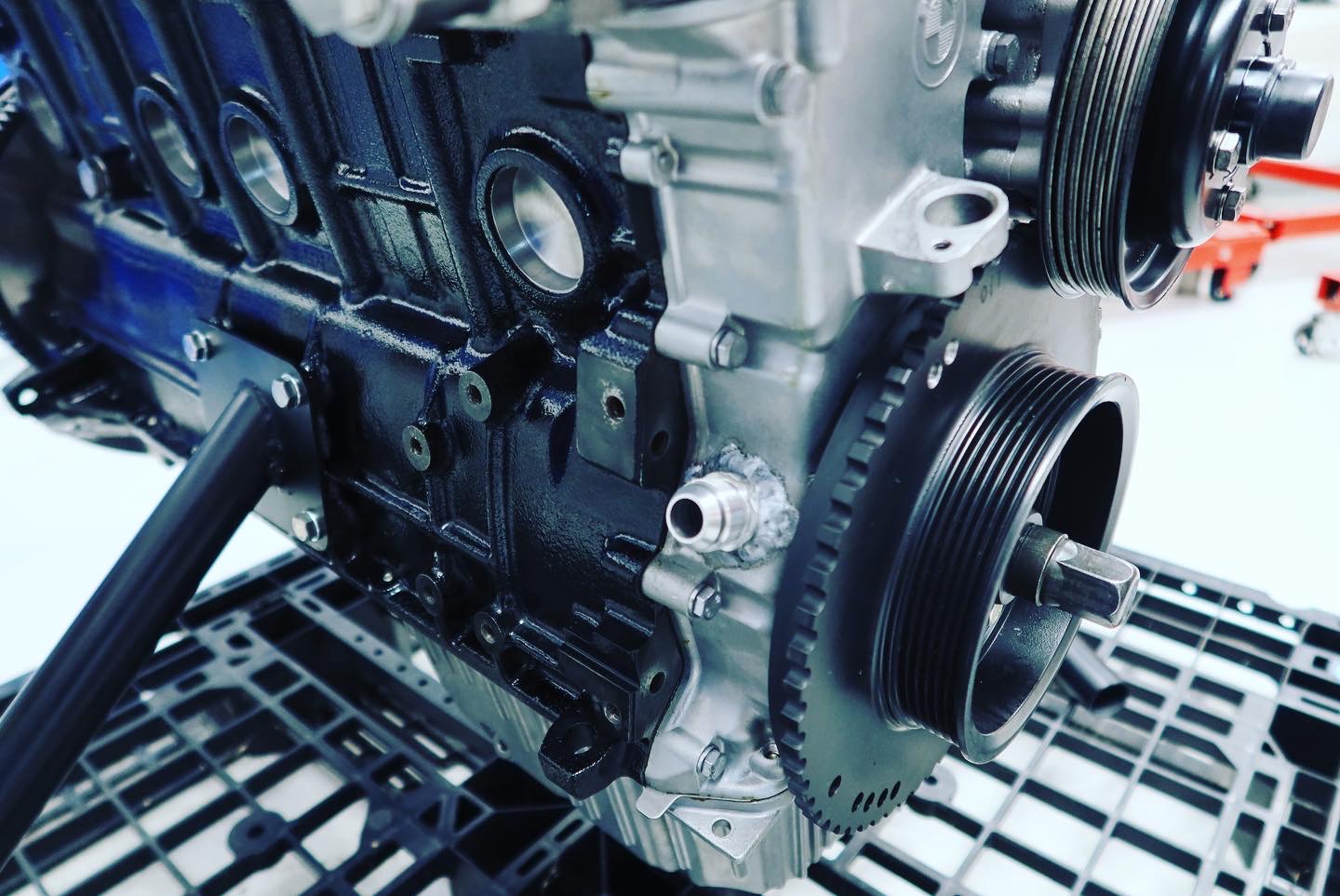

- VAC Motorsports Oil Pump Upgrade Kit

- Hack Engineering Oil Pump Chain Tensioner Upgrade

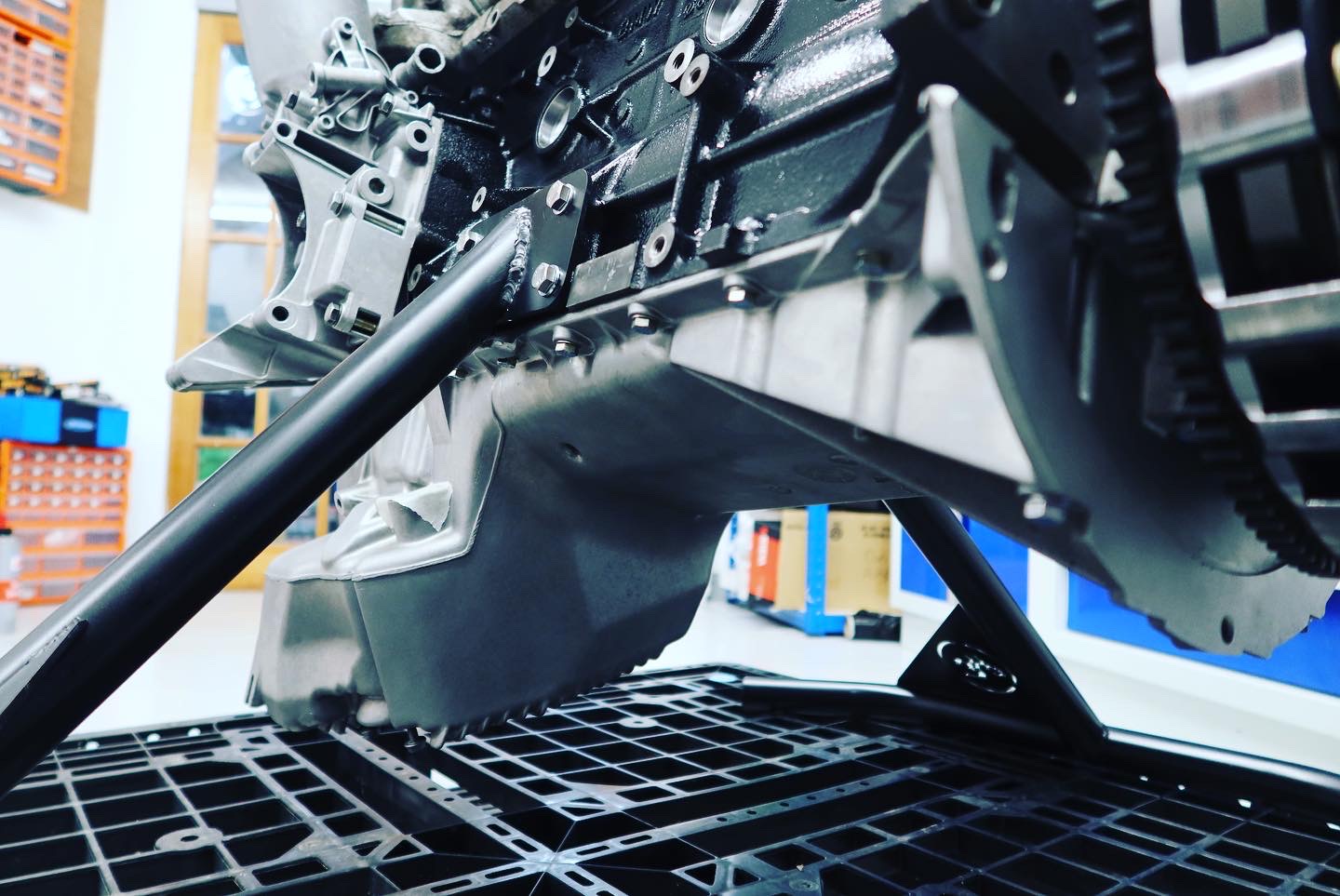

- VAC Motorsports Sump Baffle

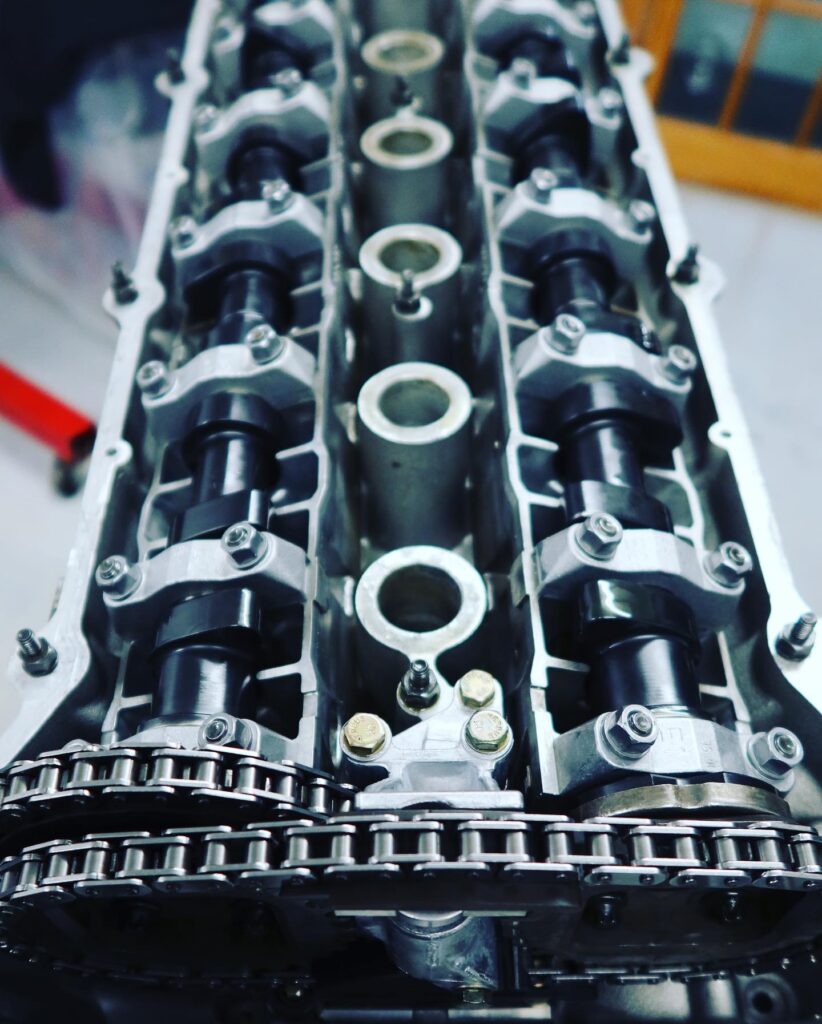

- VAC Motorsports Turbo Cams

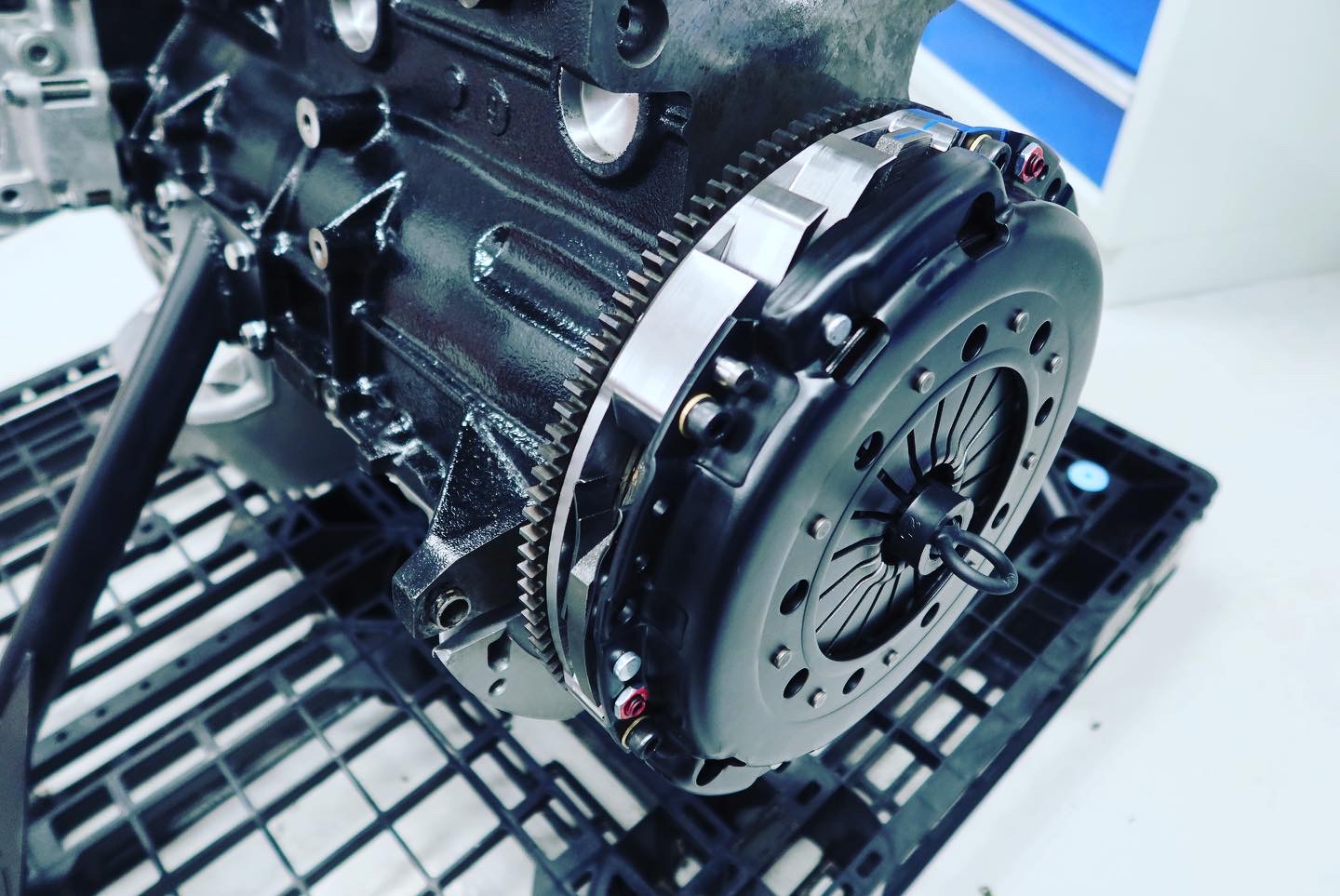

- Twin-Plate Clutch

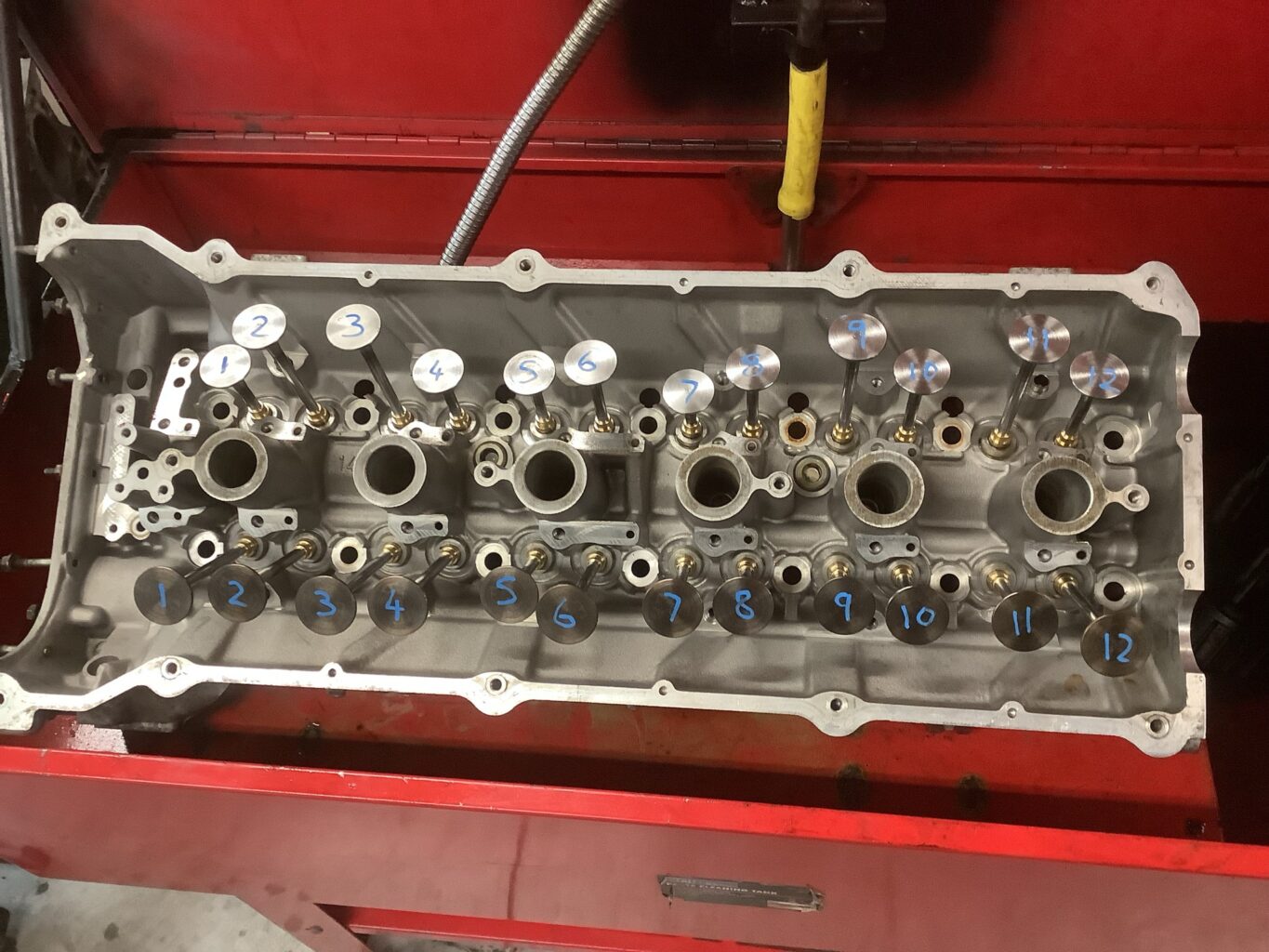

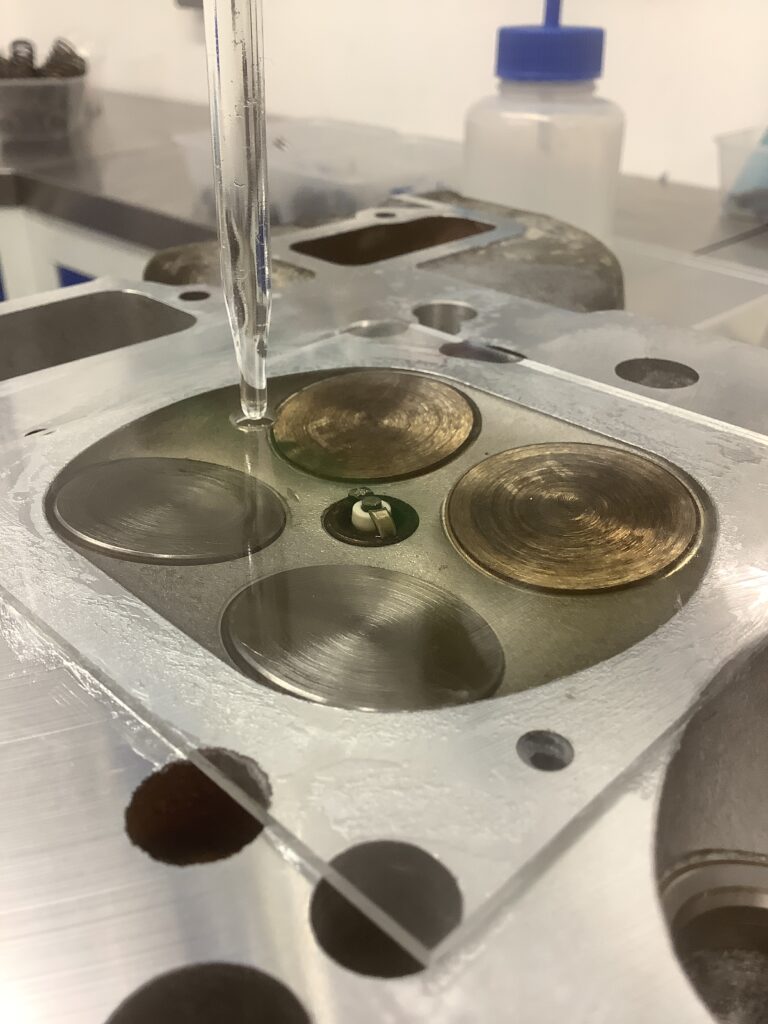

- Refurbished cylinder head including renewed valve guides and re-cut valve seats by Hack Engineering Machine Shop

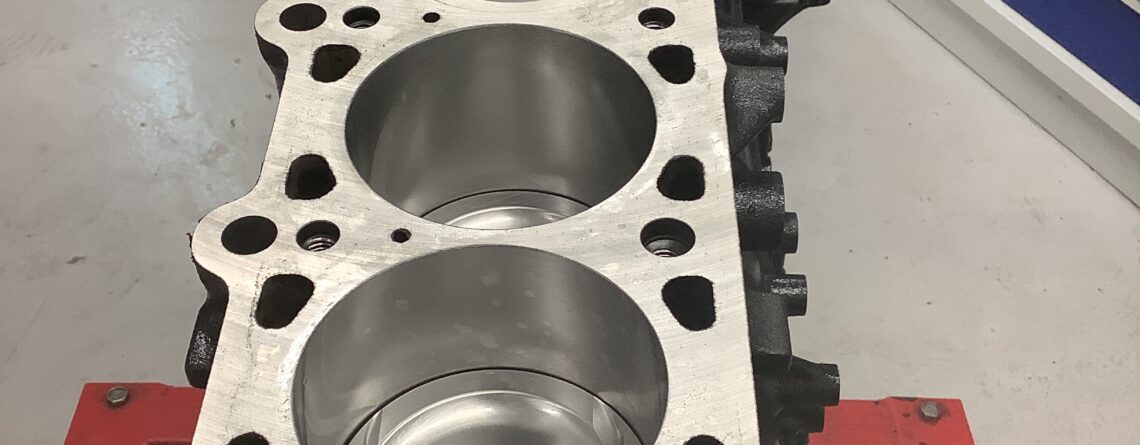

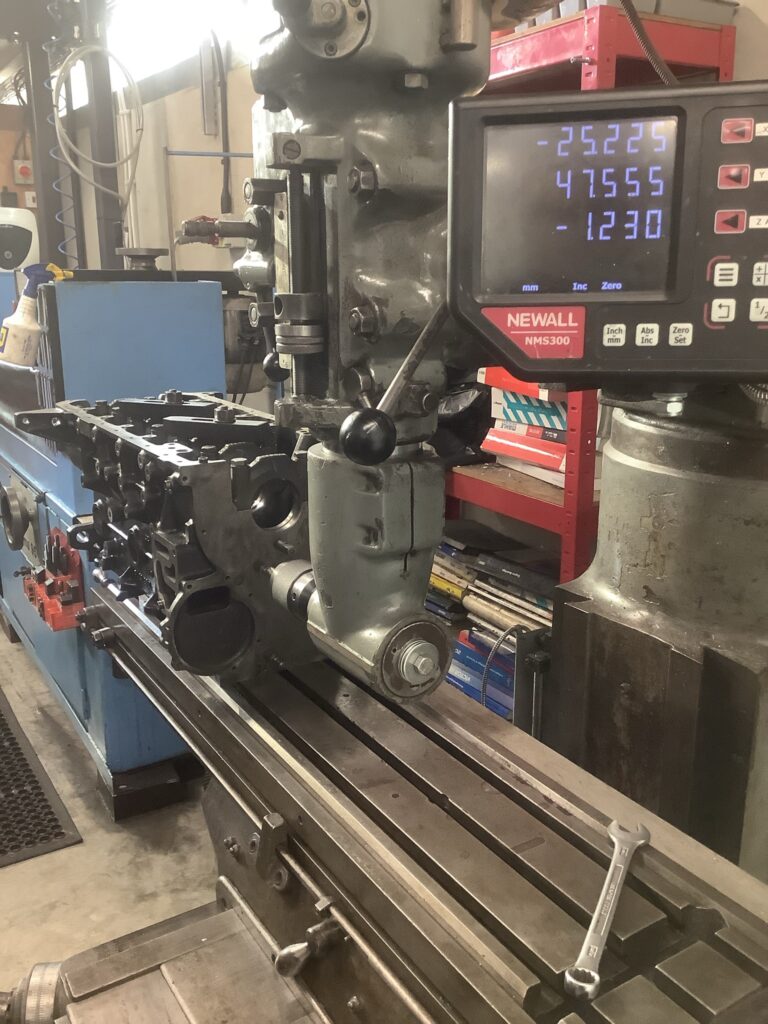

- Bored, honed and plateau-honed cylinder block by Hack Engineering Machine Shop

- Meyle Water Pump

- Many other new/refurbished parts

The first step, as ever, was plenty of machine work. Hack Engineering Machine Shop handled boring, honing and decking the block for Wiseco 85mm pistons as well as machining it for a Hack Engineering Oil Pump Chain Tensioner Upgrade. The cylinder head was treated to new valve guides, re-cut seats and a full refresh.

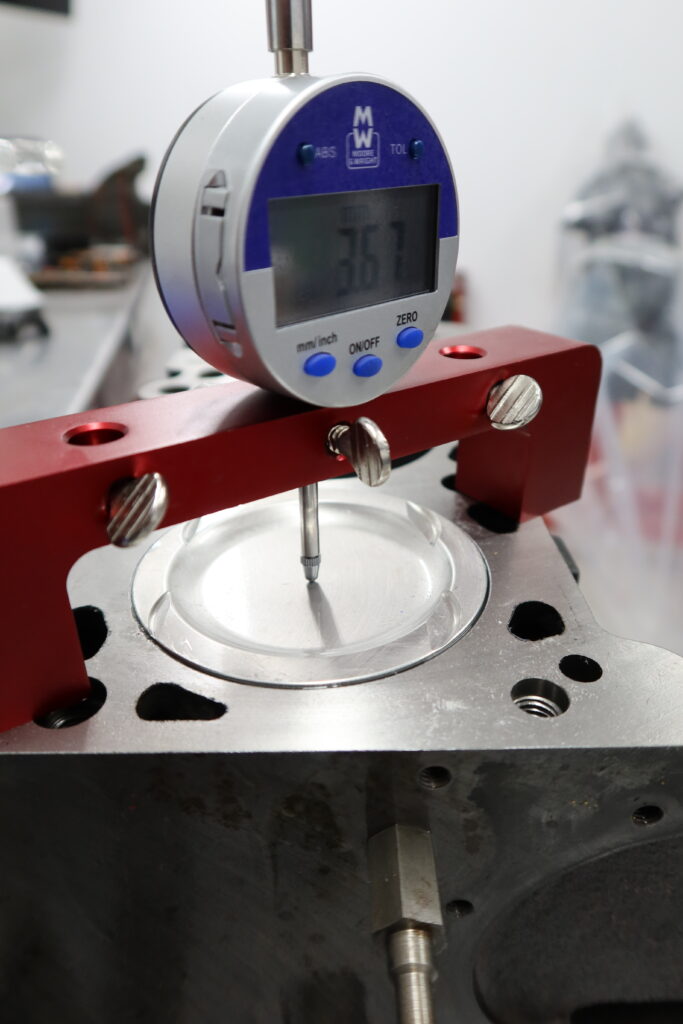

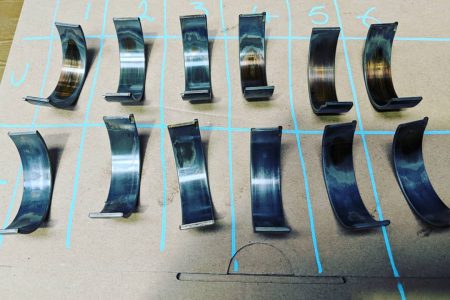

The engine was then built up, being fully balanced and blueprinted as with all of our builds. The internals of choice were SP Components con-rods to go with those Wiseco pistons, with ACL Bearings and ARP hardware.

With all measurements complete (verifying operating clearances, compression ratio and camshaft timing), final assembly could begin. The result is an engine that we cannot wait to see used in anger – perfect for Jack’s E30 turbo project.